From cabinets to birdhouses, wooden cleats hold projects securely in place. Learn about their construction and benefits here

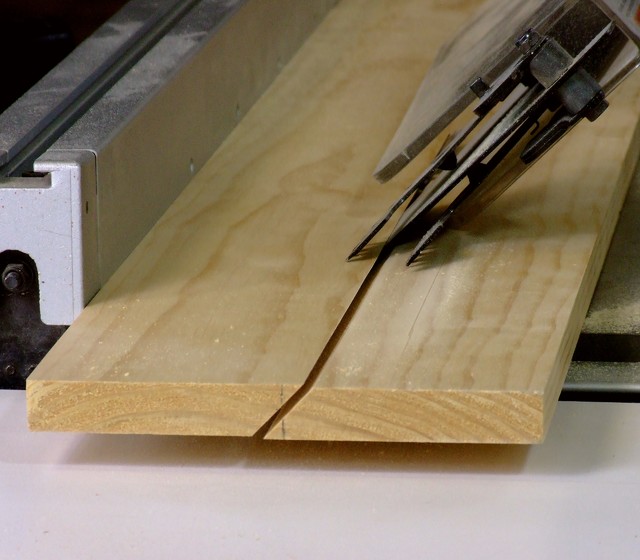

Cleats are one of the most basic methods of hanging something on walls, but they’re often overlooked. Attaching them requires slightly more time and effort than attaching cabinet hangers, keyhole hangers or picture hooks, but their capacity to support heavy loads, especially when the cleats are attached to wall studs, makes the effort worth it.I’ve used a French cleat, which features two interlocking parts cut most often at a 45-degree angle, many times over the years for various types of projects, including a TV cabinet, a headboard and even a birdhouse.

|

|

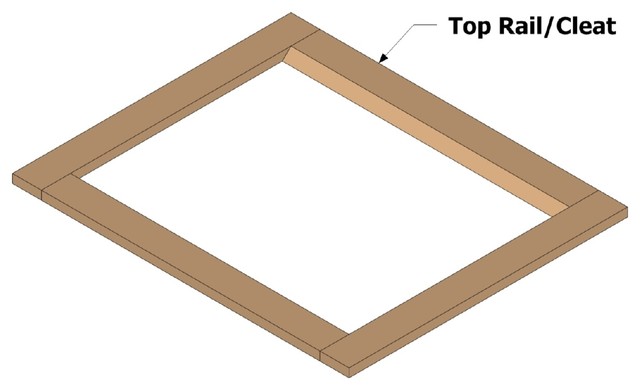

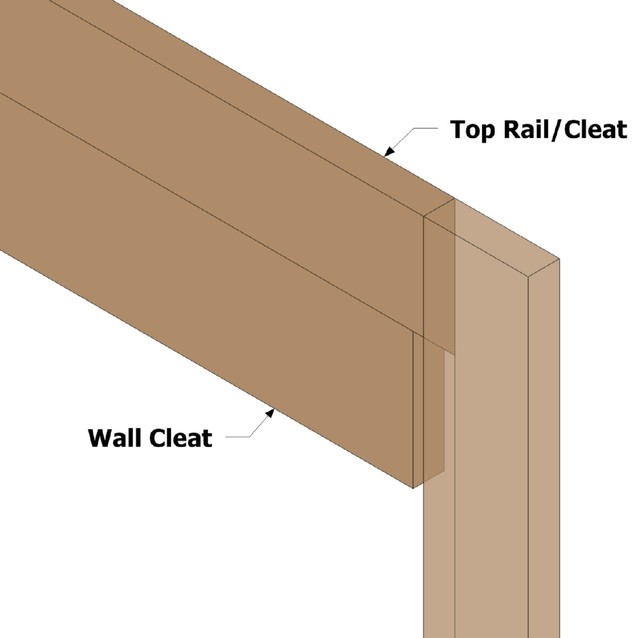

How Cleats WorkCleats in general feature two parts. One is connected to the project (project cleat), and one is attached to the wall (wall cleat). Here it is easy to see how the two parts of a French cleat fit together. The bottom part is attached to the wall (notice the screw holes). I always recommend attaching heavy projects to as many wall studs as possible.You can base your screw placements on the width of the project (and the cleat), and the position of the screws relative to the studs. For smaller projects that can’t be placed at a stud, use heavy-duty wall anchors.

|

|

|

Project UsesFrench cleats have long been used by cabinetmakers to hang cabinets, but they can be useful for any number of projects, even something as simple as a birdhouse.

|

Great article Via Houzz by Chris Hill

|

|

Here, with safety equipment removed for clarity, you can see the blade slicing through the board.More: See how to use a French cleat to hang a headboard

|

Speak Your Mind